Technology

Sagiv’s expertise in blending the technologies of hot forging and precision machining under one production roof gives the plant great power to create, innovate and control. For this reason we are often asked to manufacture products of highly sophisticated design.

|

Raw materials usedThe main materials are copper alloys, brass and DZR brass approved for use with drinking water. All these materials used by Sagiv meet stringent European quality control standards. |

|

Hot forgingWe have a number of advanced high-speed presses that process raw materials at the rate of 3000 units per hour, with each ingredient weighing up to 3 kilograms. Our processing rate of raw materials at the plant is around 250 tons per month. |

|

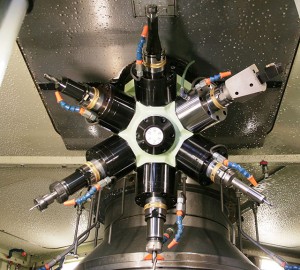

Precision machiningIn our precision engineering department we machine the forged bodies using a number of technologies: multispindle, multiflex, machining centers, transfer and CNC. This department is also set up to handle rods as raw material. These stages result in precise components that can vary in size from ½” to 2”. The machining process is computer-controlled at every point in the production chain – loading, unloading and cleaning. |

|

AssemblyThis is the stage that converts all components into the finished product. It includes adding parts that have undergone pressing. It also integrates other parts made from engineering plastic, stainless steel, rubber, Teflon and other materials – whatever is required to complete the final product. |

|

Quality controlAll final products are inspected at the end of the assembly stage before shipment. |